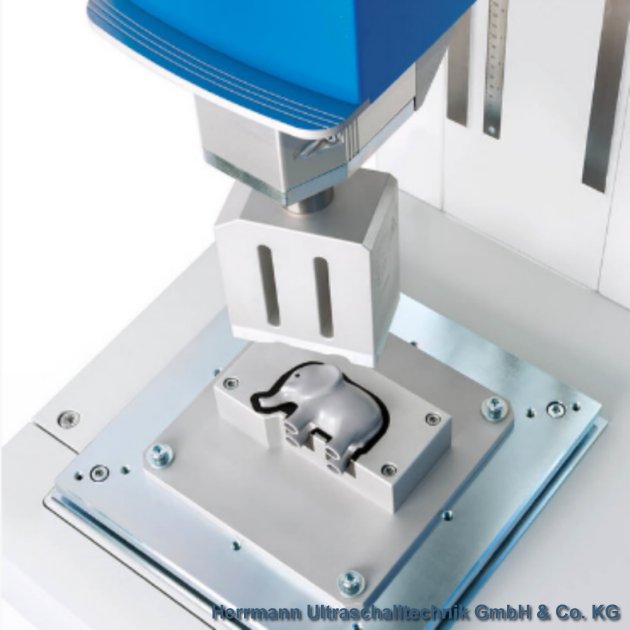

Ultrasonic welding

In order to firmly join components (e.g. two half-shells) made of thermoplastic materials, we use the ultrasonic welding process.

Mechanical vibrations (20,000Hz – 35,000Hz) of the plastic parts to be welded generate frictional heat at the molecular level on the contact surfaces of the plastic. This heat causes the plastic to soften and begin to fuse at the contact surfaces. In this way, the components join together in a form-fit as well as a material-fit manner.

After a very short holding time under pressure, the components to be joined are firmly bonded together at the molecular level.

Through this welding process, we have further expanded our production portfolio and can offer you higher product flexibility (design) as well as higher manufacturing flexibility. Also, if necessary, manufacturing costs of existing products can be reduced. If required, our design team will adapt your product to achieve an optimal welding result.